Nanomedicine and Nanoscience Technology: Open Access

Research Article - (2021) Volume 1, Issue 1

Magnetohydrodynamic Enrichment of Magnetic, Nonmagnetic, Superconducting Particles and the Molten Metals Under Influence of the Sinusoidal, Rotating Magnetic Field

Received Date: Oct 09, 2021 / Accepted Date: Nov 18, 2021 / Published Date: Nov 25, 2021

Abstract

The paper presents experimental data on the optimization of Electromagnetic Separation (EMS) as a function of the chemical powder composition, particle dimensions, and magnetic field amplitude. That method permits EM-separation in the magnetic fluids of superconducting (HTSC), magnetic, nonmagnetic particles, and molten mixes in a moving and Rotating Magnetic Field (RMF) generated with the helping of a three-phase linear asynchronous AC motor. This is achieved by the periodic compression and rarefaction in RMF, where is generated of the waves, which appear in the magnetic fluids and moves in the travelling direction of the field. Based on these results, it is shown that the "concentrates" are an enriched mix of magnetic, conducting, or nonmagnetic powders with optimal quality and the "tails" are the recycle fractions requiring additional thermo chemical treatment. EMS may be used as an express method for the evaluation of powder quality and quick correction of synthesis parameters. With a new method developed author in the same time, it was discovered the successful segregation of the molten metals under oscillated and a rotating magnetic field generating by linear form AC-motor.

Keywords

Electromagnetic enrichment; EM-separation, Magnetic and superconducting particles; Three-phase linear asynchronous AC- motor; Magnetic liquid; Rotating magnetic field; concentrates; Tails; Molten metals.

Abbreviations

EMS: Electromagnetic Separation, RMF; Rotating Magnetic Field; Phosphate Buffer Saline (PBS)

Introduction

Physical phenomena in magnetic fluids are sometimes quite unusual, due to the unique combination of strong magnetic properties and fluidity [1-6]. It is known that a rotating magnetic field rotates fluids that have magnetic anisotropy. In magnetic fluids, this effect is naturally much more pronounced. Moreover, the rotation of the magnetic moment can cause the rotation of the particles themselves. Due to viscous friction, adjacent layers of liquid follow the particles. Thus, in a rotating magnetic field, particles become centers of micro-vortices in a liquid, the sizes of which are comparable to the distance between them. The ability to control a fluid using a magnetic field is attractive for solving various technical problems. Artificial liquid media, which are colloidal solutions of highly dispersed particles in carrier fluids. When the magnetic field is turned on, the viscosity of the suspension of magnetic particles increases for various reasons. The presence of inter particle interactions in the system is possible for the aggregation of a sufficiently large size of magnetic particles due to structural transformations. The rotational motion arising in it due to their magneto-dipole interaction excites translational degrees of freedom. As a result, the pressure forces due to particle collisions weigh the powder. The forces of the intrinsic field of a magnetic fluid lead to the formation of very peculiar equilibrium structures, which, depending on the conditions, can have a complex character. Changes in the field with time cause corresponding changes in the surface: a travelling magnetic field generates a travelling surface wave. This mechanism leads to the conclusion that the relaxation of magnetization is determined by the slow orientation of the directions of the spontaneous magnetization of aggregates and the rapid orientational ordering of particles along the preferred direction. An inhomogeneous magnetic field is capable of setting a periodically changes in time magnetic fluid in motion which excites periodic movements, i.e. oscillations.

When the characteristics of the surface wave excited by the magnetic field coincide with the characteristics of natural waves, the most favorable conditions are created for the transfer of energy from the magnetic field to the wave, and its excitation will be resonant.[1-6] The condition for the onset of resonance is such a relationship between the frequency and the period of the driving force, which corresponds to the relationship between these quantities according to the law depending on the amplitude of the alternating field. This means that the free surface of a liquid, as a surface of constant pressure, located in a periodic magnetic field, will be wavy, representing a system of troughs and elevations corresponding to the minima and maxima of the magnetic field. A travelling magnetic field is capable of creating the rarefaction and compression waves, which move in the direction of propagation of the field, which in turn triggers periodic rotating of the particles. The tangent tension to the boundaries of the material elements of the liquid also contributes to this rotation. Unusual phenomena in a magnetic liquid cause ruptures and shock waves. In magnetic hydrodynamics, the rupture surface is the surface of the material in a medium, in which either thermodynamic or electromagnetic values or both are jumping. Such a break is called a contact break and the fracturing surface is an interface between two fixed media. If the velocity and strength of the magnetic field are parallel to the fracturing surface and can experience surges thereon, arbitrary in magnitude and direction. In that case, a break is called tangential. It is possible in both compressible and in-compressible environments.

Jumps of other thermodynamic quantities are determined by using the equation of state and is rotational [5-11]. Simultaneously, due to the convection of the paramagnetic liquid by the magnetic field, stratification in the flow along the gravitational field occurs, that promotes an additional separation in the initial mixture.[1,2,12-15].This goal is achieved by the fact, that in the method of electromagnetic separation in a travelling magnetic field, the material is processed in a flow of a paramagnetic liquid, and the mixture is additionally treated with a non-uniform rotating magnetic field with a gradient perpendicular to the flow of the separated material. The vector of the travelling magnetic field is directed in the opposite direction to the direction of the flow movement of the separated material. This is achieved due to the occurrence of periodic weighting in a travelling magnetic field, since in a paramagnetic medium wave of refraction compression arise, as well as objective conditions for the separation of mixtures of dissimilar particles as a result of the action of forces in different directions (magnetic and gravitational).

Thus, free gravitational-capillary waves propagate on the surface of an infinitely deep layer with the frequency and wave number, which are related by the relation in magnetic fluids. Taking into account the perturbations of the magnetic field, the dispersion equations have a more complex form, from which, in particular, it follows that a magnetic field collinear to the wave vector increases the frequency of the waves, and decrease it perpendicular to its surface. The rotation of the magnetic moment can cause the rotation of the particles themselves due to the viscous friction, the adjacent layers of liquid follow the particles [6]. As a result, a stream of particles appears in this region of space, accompanied by a decrease in the energy of the system. If one has a simultaneous local rotation of the liquid element in direction of rotation of the field, the lag in the direction of the magnetic moments of the particles from the field for a given fluid element decreases, and consequently their potential energy in the field also decreases. The growth of the local concentration of particles leads to an increase in the moment of forces acting on the element liquid and, as a consequence, to an increase in the angular velocity of its rotation. In that case, a magneto-disintegration of the powder by an alternating field is carried out. The coexistence of suspensions of both magnetic and superconducting mixtures of powders in a magnetic fluid, when a running rotating magnetic field is applied creates favorable conditions for electromagnetic separation [8-12]. The author also performed a large number of experiments on EM separation of molten metals, containing both magnetic and diamagnetic components. To separate the liquid phases, the direction of the travelling EM field was switched to the opposite by switching the phases of a linear asynchronous motor. Fractions with components Fe and Cu moved in different directions, which contributed to their successful removal from the melt [16-20].

Materials and Methods

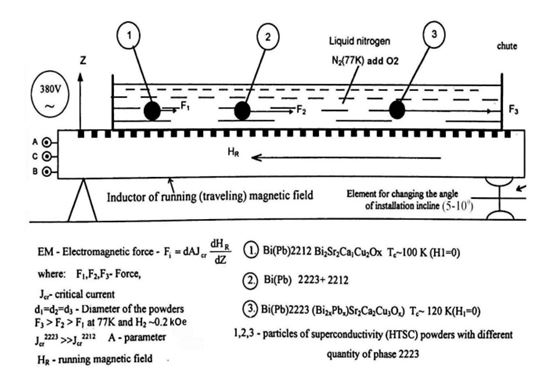

Numerous experiments with multi component mixtures of ferromagnetic, paramagnetic and nonmagnetic particles have demonstrated of the possibility the enrichment of the powders composition, also segregation of the molten metals under oscillating and rotating magnetic field generated by AC-motor (0.5-1 kW) (Figures 1-3) in the magnetic fluid with different magnetic properties as the effective original method of EM-separation. [8-12]. The AC-motor has generated the moving and rotating magnetic field (RMF) -0,5-5.0 kOe, which is similar to an electromagnetic transformer with special winding A.C.B (Figures 1 and 2). The stator serves as the primary winding of the transformers, and the rotor was as the secondary winding, where magnetic fluid has generated the process of the powders separation. With the only one of the lower winding, a sinusoidal gradient vertical magnetic field is formed. In the gap for twin winding of the stators magnetic field has equal character (Figure 2).

FIG.1. Asynchronous motor with one hand own (Israel).

FIG.2. Stator with twins winding (Russia).

FIG.3. Shem EM separation of the HTSC powders.

EM-properties of powders were being measured by the original unit, including coil and inert capsule with powder under a magnetic field of 1-10 Oe and frequency 200-800 kHz . This unit has been connected with a programmed RCL- meter (Fluke) and a set of parameters of the coil with HTSC powder were measured simultaneously. All measurements had been run followed by heating under a magnetic field (”diamagnetic shielding”). For separation of the HTSC powders they were placed on the Pyrex- glass surface reservoirs with liquid nitrogen (with an addicting small percent of oxygen O2 for receiving paramagnetic mix after 1-2 days in storage when the paramagnetic properties are formed). Powders containing magnetic, superconducting, and nonmagnetic fractions preliminary ground to a level of 5-30 μm had been sifting through holes in sieves of various diameters, to obtain particles that were uniform in volume. A similar operation was necessary, since the reliability of the separation results depended on it. HTSC granules with size 5-10 μm were selected not to damage the single crystals inside the grains [21]. The traveling magnetic field had been switched on after cooling an HTSC-powder in the cuvette of the uniform grain of size (10-50 μm ) in liquid nitrogen with additions of several percent's O2:

H [t,a] = Hm sin (t ± a) (1)

where t=ω t = (2π/T)t, a = (2π/Tn)m, T is the time period of the wave, Tn is the spatial period of the wave, Hm is the amplitude of the RMF, ω is a frequency of the moving magnetic field. As results, in magnetic liquids of the variable induction changing harmonically and the magnetization J lag is behind the field and its size is less than in the case of a balance at the peak value of a field:

J = J0 cos (ωt – δ) (2)

The growth of the local particle concentration leads to an increase in the moment of forces acting on the liquid element and, as a consequence, to an increase in the angular velocity of its rotation. The development instability leads to the formation of a periodic structure of local clusters of particles from non-magnetic and non-conducting material that will start to rotate in a direction opposite to the direction of rotation of the field [8-12]. For the superconducting powders at a fixed size, the speed, with which each superconducting powder is moved depends on the SC transition temperature Tsc, enabling segregation fraction, according to their respective critical currents (Figure 3).This interaction forces in HTSC particles proportional to the critical current (Icr), the diameter of particles (5-30 μm), and ω is a frequency of variable electromagnetic field [23]. The motion of the magnetic particles perpendicular to the inclined plane is possible when the magnetic force - F is greater than the normal component of the force, and the resultant force must be:

F = Fmagn - g cosα (3)

Where, α (5-10o) is the angle of the separator inclination.

The EM- force Fac, moving the HTSC- particles is the result of the interaction of the fractions with the traveling (running) EM-magnetic fields (RMF) in the colloid:

Fac = BIcrR2ωτ /η (4)

where: ω is a frequency. Icr is the critical current the HTSC- fractions, R is the radius of particles, B is the value of the induction of running (spatial and time alternating) magnetic field, η is the viscosity of the liquid, τ is the pitch of the winding stator. In according to [24], the influence of the levitation electromagnetic force- FZ on the HTSC- particle is given by :

FZ = M dBz/dz , M = VD A Icr (5)

here D is a magnetic moment of grains, V is a volume of the SC fraction, A is a geometrical factor depending on the shape of the sample, Icr is the critical current density, B is the amplitude of the induction RMF.

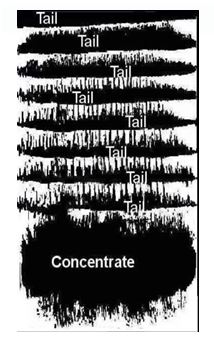

Fmagn is magnetic force in RMF that acts on all particle, that have a magnetic moment:

Fmagn = μ0 χ H grad H (6)

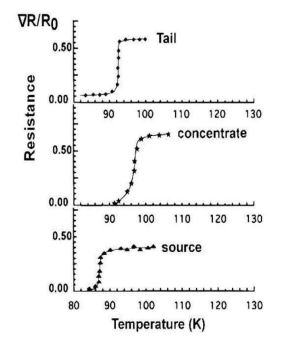

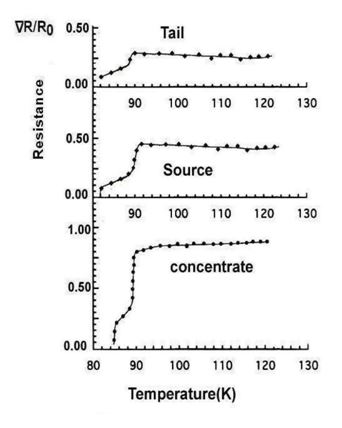

H is a magnetic field, χ is a magnetic susceptibility of the particle, μo is the magnetic permeability of vacuum. The negative effect is significantly amplified in the case of chemical non-stability during storage and processing powders. Partially degraded powders also were treated by EMS. As a result of separation, the powders were divided into "concentrate" and "tail" fractions. These differences and advantages are the next ones: high speed the process means its simplicity, high quality of separating particles of different electromagnetic properties, possibility of managing separation process depending on material type, on its phase structure, on values of the characteristic parameters (Tcr, Icr, Hcr Δtc). The correlation between the speed of the HTSC (123) particles and the percent of the oxygen (Ox) in YBa2Cu3Ox was discovered. Since the temperature of the SC-transition has a linear dependence on the oxygen percentage, the knowledge of Tc and speed moving HTSC particles during the separation may immediately (in 10 sec) to give a percentage of the oxygen in the chemical structure of HTSC of new materials. A significant difference in hereditary properties for these fractions was discovered. As may be seen after the process of the separation on Figures 4-6 from source HTSC have received two parts, which are concentrate and tail.

FIG.4. The hereditary in resistance of the thick film from percent oxygen - X in YBa2Cu3Ox (source, concentration, tail) before and after EM-separation.

FIG.5. The heredity temperature and impurities dependence of the resistance in BiPbSrCaCuO films (22112 and 2223 phase structures), where concentrate, with more percent 2223 phase after separation process. In tail Bi(HTSC) second phase (2223) transition is missing.

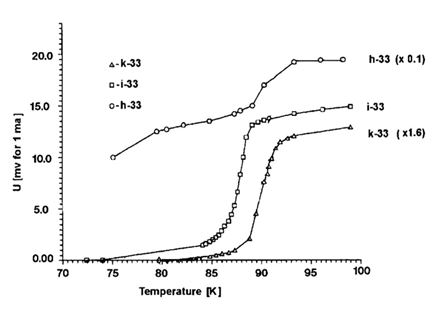

Fig.6. The hereditary in resistance difference in the thick films, which were made from powders YBa2Cu3Ox for source (i-33), concentrate (k-33x1.6), tail (h-33x 0.1), before and after EM separation

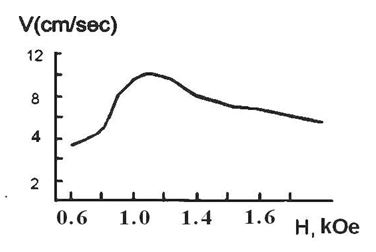

Thick-film produced from concentrated YBa2Cu3Ox are demonstrated interval of SC –transition decreasing and twice rising its Icr (Figures 4 and 6). Thick-film HTSC- on basic BiPbSrCaCuO- was divided as the function in their content ( 2212 and 2223), where in the concentrate, more 2223- phase is seen (where SC-transition occurs at 110oK and tail phase, 2212 , has TC ≈ 90oK (Figures 3 and 5). Temperature and extraction the fractions characterized by higher critical currents by EMS permit to disintegrate and improve properties HTSC- powders, by a force, proportional to an amount superconducting (HTSC) phase in a particle. Non-monotony behavior was observed in RMF. More than 1 kOe of the growth speeds of the moving particles slowed down because ` magnetic field penetration inside the particles destroyed the superconducting phase in YBa2Cu3Ox (Figure 7). Besides, the particles must be open, one-dimensional, sharply differ in magnetic and gravitational properties and move freely in the direction of separation at a given speed. The mixture is divided depending on the magnetic susceptibility of the particle, the conductivity, and the specific gravity of the particles.

Fig.7. The behavior of the velocity of moving HTSC -particles as a function of the value EM-field.

For the fixed particle size, the rate at which each superconducting particle moving in the opposite direction to the motion of the magnetic field particle, allows the segregation particles to correspond to their properties. EMS permit to disintegration improves properties HTSC powders, by a force, proportional to an amount superconducting (HTSC) phase in a particle. Temperature and extraction of the fractions are characterized by higher critical currents (Figure 3).

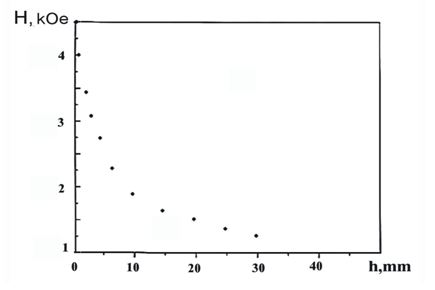

A mixture of powdered minerals, slags or mixtures, pre-crushed to a partial loss of disclosure, is placed in a salt solution having paramagnetic properties, for example, manganese chloride in a cuvette, which is then installed between the poles of an electromagnetic system, which is deployed stator of an induction motor, including alternately, both windings of the traveling field inductor, then one lower. Moreover, at the first stage, the windings are fed with a weak current, creating a uniform running magnetic hearth within 0.5 kOe, removing particles with a strong magnetic moment from the mixture, and at the second stage, the mixture is treated with a strong inhomogeneous magnetic field above 2 kOe created by one lower winding of the inductor, as a result, the mixture is divided depending on the conductivity and specific gravity of the particles. Both windings of the inductor are preliminarily inclined with the cuvette at an angle of 5-100 to the horizon for efficient separation and removal of separation products Figures 8-10.

The mixture is divided depending on the magnetic susceptibility of the particle, the conductivity, and the specific gravity of the particles. The mixes with components of the different compounds A and B: were divided into two parts:

A- The magnetic concentrate - Cu-0.8 %, Fe-38%, Zn-12.5%,

The output has made - Cu- 4.5%, Fe-12.5%, Zn-2.8% (the initial contents Cu-1.3%)

B- Has been divided also into 2 parts

First, of the In concentrate (1) and tail (2):

(1) Zn-2.04%, Cu-1.31%, CaO-6.63%, SiO2-14.32%, Fe-60%, Pb-0.35%.

(2) Zn-0.85%, Cu-0.3%, CaO-6.83%, SiO2- 27.90%, Fe -13.69%, Pb-0.23%

Fig.8. Gradient magnetic field over the stator.

Fig.9. Attraction to the poles of an electromagnet of HTSC fractions containing small %O2 with strong magnetic properties (Tail).

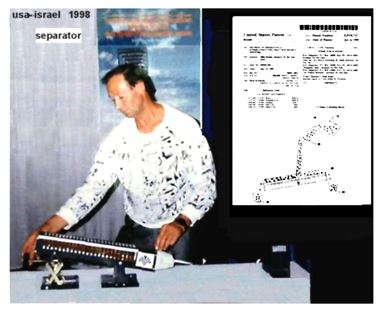

Fig.10. Demonstration of EM-separator on the Exhibition USA-Israel.

Conclusion

The EMS- method is based on applying the electromagnetic force to the HTSC-particles and extracting a concentrate enriched by those granules that have a high critical current from the mechanical mixture of the powders. Ferromagnetic particles were attracted to the bottom stator of the asynchronous motor and were removed. For particles in a traveling non-uniform magnetic field, the force acts proportionately to a value of magnetic moment, conductivity, and size

of HTSC- particles. That provides the possibility to receive after separation of the powders from source in two parts, which are concentrated, where have better properties.

- RMF induces waves of the dense with followed by strong hydrodynamic effects in the paramagnetic liquid (rotation and oscillations in all points), that promote mechanical separation of soft agglomeration.

- Perpendicular convection of the liquid by oscillating and rotating also promotes additional segregation in the initial mixture of solid particles.

- For the division of a mix of waste products of non-ferrous metals in a magnetic separator created force should be more than a set of mechanical forces of coupling. Besides particles that should be only one diameter, besides particles that should be only one diameter, are distinguished on magnetic properties.

- It was shown that the "concentrates" are enrichment powders with optimal quality and the "tails" are the recycle fractions needing additional thermo-chemical treatment.

- EMS may be used as an express method for evaluation of powder quality and the quick correction synthesis parameter. Since the SC transition temperature (Tc) has a linear dependence on the percentage of oxygen, knowing the speed of moving HTSC particles during separation can immediately (10 seconds) obtain the percentage of oxygen in the chemical composition of HTSC from new materials.

- Many evidence pointing to that successful segregation in a magnetic fluid of the powders and of the molten metals under oscillation and a rotating magnetic field generated by AC-motor is a new method developed by the author of that work may be recommended as a perspective for industries waste utilization. [23]

Acknowledgments

Prof. Ya.G. Ponomarev (MSU, Dep. Phys. Low. Temp for the reading article and useful censorious remarks, Ing.M.Broide and D.Rubin for helping, Ing. A. Fadeev ("Rosna", Ltd, Russia, Ekaterinburg) with the manufacturing of HTSC-thick films. The Nd-HTSC powders were prepared by Dr. G. Shter, YBaCuO (123-compound) was produced in the Chemicals Plant (Ekaterinburg, Russia). Bi(Pb)-HTSC was synthesized in Kharkov Institute of Monocrystals (Ukraine), Prax-air (USA), Czech Republic, These investigations were been supported by the Russian Nationals program and Israel Incubator financial support. Prof. Y. Yeshurun and Prof. E. Zeldov (Weizmann Sci.Institute, Rehovot, Israel) for help (Israel)

References

- Rosensweig RE. Ferrohydrodynamics. Cambridge Univ Press. 1985;

- Berkovski BM, Bashtovoy V. Magnetic Fluids and Applications Handbook. 1993.

- Shercliff JA. A textbook of Magneto-hydrodynamics. 1965.

- Berkovski BM, Medvedev VF, Krakov MC. Magnetic Fluids. 1989.

- Shliomes MI. Magnetic liquids. 427-458.

- Ya Blum E, Zebers AO. Hydrodynamic of the magnetic liquids. 1989.

- Borovoy AA, Finkelstein EB, Cheruvimov AN. Laws of electromagnetism, Nauka, Glav.red. fiziko-matematicheskoÄ lit-ru. 1970.

- Broide EL. The Separating SC-Fraction from a Mixture. US.Patent. 1998.

- Broide EL. Electromagnetic separation of the YBaCuOx, Nd-HTSC and Bi-HTSC- powders. J Supercond Novel Magnet. 2008.

- Broide EL. Superconductor and Cryoelectronics. 1998: 33.

- Broide EL. Superconductor Week. 1998.

- Broide EL, Shter GE, Grader GS. Enrichment of NdBCO superconductor powders by EM-Separation. Abstract Int Conf. 1999.

- Terentiev AN, Kuznetsov AA. Rotation of a levitated YBa2Cu3O7-X, superconductor due to a low-frequency magnetic field. Physica. 1990; 169:112-116.

- Belyaev B, Smorodin BL. Convection of the magnetic fluid under alternating magnetic fields. Russian J App Mech Tech Phy. 2009: 50:4.

- Barsoum M, Patter D, Lady S. Appl Phys Lett. 1987:51-23.

- Subramanian MA. HTSC: Structure, obstacles, nonstoichiometry and correlations of Tsc, superconductivity. Phys Chem Techn. 1990; 2:175-185.

- Dobromyslov AV, Dolgih GV, Talutz GG, et al. Physics of Metallic Materials. 1988; 65:763-770.

- Phillips JC. Phys of HTSC. 1989.

- Petrov ML, Popov GV. Superconductivity. Phys Chem Techn. 1990; 3:77-82.

- Dzugutov BM, Podshevskih HA, Fisher LM. Superconductivity. Phys Chem Techn. 1990; 3:52-61.

- Lee YC, Kang H, Linux C. J Phys C. 1988; 21:L639-L64221.

- Maeda Y, Tanaka M. Tassano F. Jap J Appl Phys L. 1988: 209.

- Broide EL. Install for the separation of liquid metals. Patent Ru. 1983; 345896.

- Sengupta S, Gaines JR. YBa2Cu3Ox levitators for magnetic bearnings.

Copyright: © 2025 This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.